Modern plastics come in all shapes and sizes, and are used in countless applications. The different materials must be, for example, particularly tear-resistant in terms of ropes or nets, withstand great pressures in the case of pallets and similar, or keep their shape as for cladding parts. The underlying parameters are mechanical properties such as elongation at break, impact toughness or Shore hardness. However, these factors not only determine the polymer’s area of application or the service life of the end product, but also require different approaches to shred and process these materials for recycling purposes in line with the concepts of the circular economy.

Modern plastics come in all shapes and sizes, and are used in countless applications. The different materials must be, for example, particularly tear-resistant in terms of ropes or nets, withstand great pressures in the case of pallets and similar, or keep their shape as for cladding parts. The underlying parameters are mechanical properties such as elongation at break, impact toughness or Shore hardness. However, these factors not only determine the polymer’s area of application or the service life of the end product, but also require different approaches to shred and process these materials for recycling purposes in line with the concepts of the circular economy.

Because of the different mechanical properties of plastics, shredder cutting systems are often specifically designed to shred a particular material. For example, the cutting geometry of pointed knives has a positive effect when shredding extremely tough materials such as big bags, ropes or nets that have to withstand high tensile loads. Here, the force provided by the drive unit focuses perfectly on a very small area, with the cutting system shredding highly tear-resistant materials as if it were a knife or scissors. On the contrary, flat knives have really proven their worth in terms of processing rigid plastics like polypropylene. Materials such as plates, crates, or plastics manufacturing residues (from extrusion, injection moulding, etc.) which are relatively thick-walled compared to fibres, can be broken down more easily over a parallel cutting edge. The knives operate over a large area and aggressively draw in material, and this, in turn, has a positive effect on throughput.

The choice of the right cutting system, or rather the interaction of rotor and stator knives and speed, also decisively influence particle quality. Here, it is particularly important to avoid fines in the material flow because they negatively affect downstream processes and can lead to blockages in cleaning components or the fine screens of extruders, for instance.

The above examples show how extensive this topic really is. The economic component in particular plays an important role here. It often happens that contract manufacturers have to accept other materials, such as lumps from production processes, along with the main material, which may be a film. Furthermore, several different types of waste plastics often have to be processed to fully utilise production capabilities. If a separate shredder is now used for each material stream – depending on the company’s size and volumes being shredded – it is difficult to demonstrate economic viability. For this reason, smaller batches are often sold on, which in turn reduces the overall productivity.

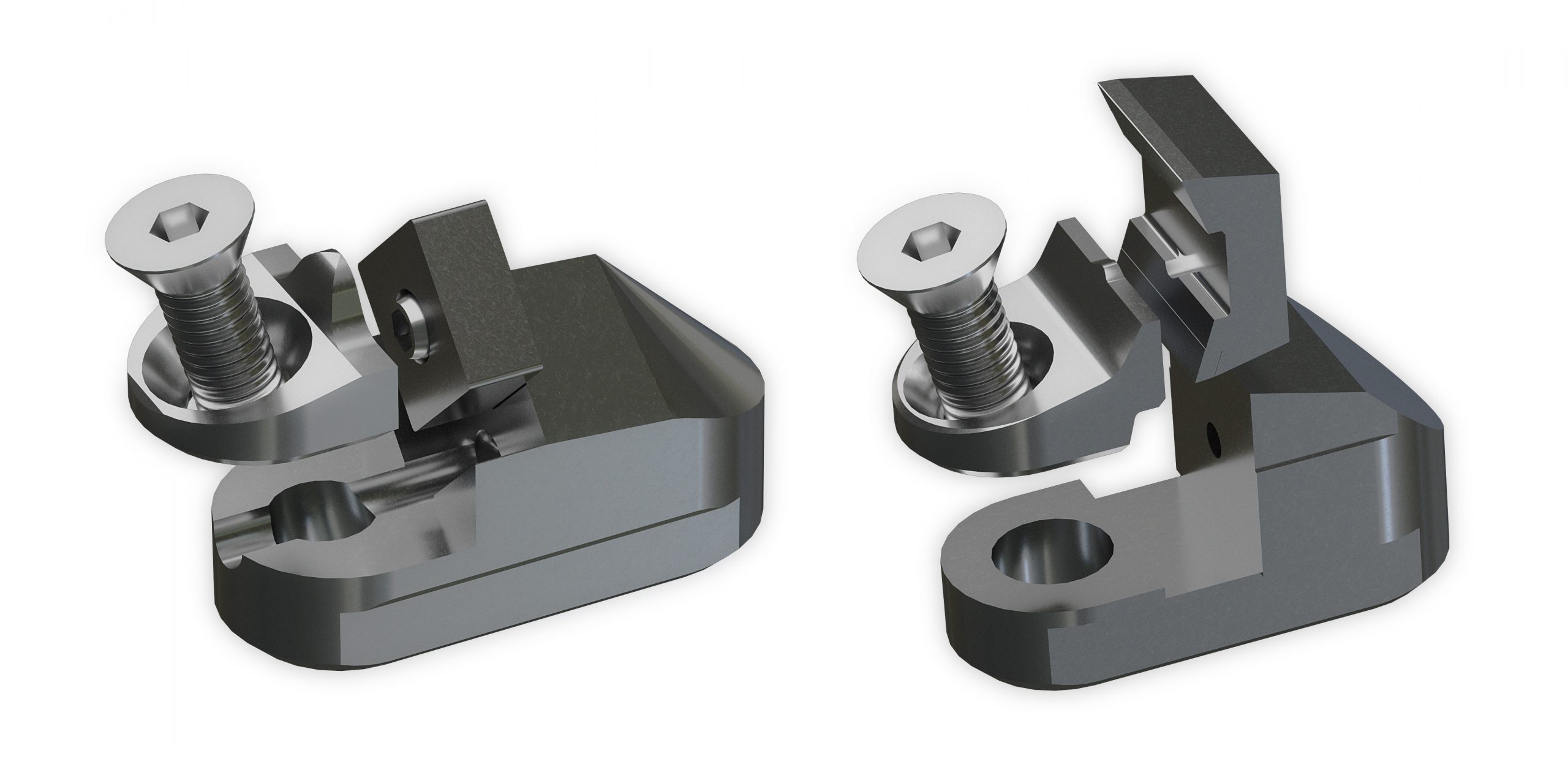

Lindner addressed this problem and turned the established Mono-Fix technology into a smart system. Thanks to the Mono-Fix – originally developed to minimise downtimes during maintenance – knives and knife holders can be changed using just one screw. More modules have now been added to the existing system. Different pointed and flat knives are available, as well as cover plates and special counter knives that can be fixed to the same rotor body. This extended range now makes it possible not only to replace the cutting system completely in the event of wear and tear, but also to use different or mixed rotor configurations. Mixed cutting systems can avoid common problems caused especially by difficult materials such as massive lumps and purgings because pointed knives would otherwise mill into the plastic, causing throughput to drop sharply. Combining the two systems produces particles that are precisely cut by the pointed knives, and the flat knives cut loose any milled-in material. Using special filler plates, the aggressiveness of the cutting unit can also be adjusted so that it is possible to shred heavy materials at corresponding throughputs even at low drive power. In addition to the flexible rotor configurations, customised software set-ups make it possible to tailor relevant machine control and frequency converter parameters to the respective application.

The turnkey packages can be ordered as material-specific options perfectly suited to the relevant application and shredder. In developing this solution, Lindner primarily relied on the application know-how acquired internationally over decades, because after all, the ideal shredder configuration for PP/PA ropes in Chile also works wonderfully on the coasts of Norway.

Knives and knife holders of the Lindner Mono-Fix system can be freely positioned on the rotor and changed with just one screw.

Knives and knife holders of the Lindner Mono-Fix system can be freely positioned on the rotor and changed with just one screw.

Mixed rotor configurations ensure hassle-free shredding of difficult materials such as massive lumps.

Mixed rotor configurations ensure hassle-free shredding of difficult materials such as massive lumps.

Frederico Hartmann é diretor comercial para a América Latina na Lindner Recyclingtech. Atua direta e indiretamente no mercado para a Lindner desde o ano de 2012, quando liderou o desenvolvimento e abertura do mercado brasileiro para esse importante fabricante austríaco de tecnologias para a valorização de resíduos. Foi o responsável direto por liderar também a posterior abertura e desenvolvimento de outros mercados na região, como o Chile, Argentina e México. Atualmente gerencia uma rede de mais de 10 distribuidores e parceiros comerciais nos principais países da região. É formado em Engenharia de Produção pela PUCRS, além de ter realizado parte da mesma faculdade na University of Miami, nos Estados Unidos.